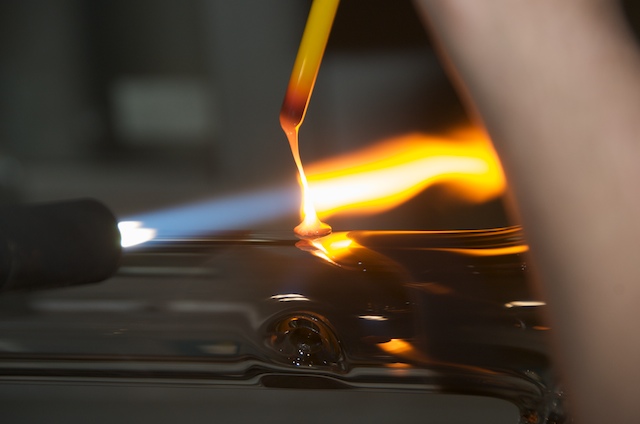

Now the same process but with yellow and a slightly less hot flame, as the yellow is prone to bubbling at to high temperatures.

Now the same process but with yellow and a slightly less hot flame, as the yellow is prone to bubbling at to high temperatures.

On to the red ice catcher

The ice catcher on the bottom that looks red is the yellow, which is still red hot from just being applied.

Pushing in the red ice-catcher.

The lathe is on and the bong is being rotated, while the flame is heating up the area where the work was done. This needs to be done do prevent cracking due to uneven surface temperatures.

You can see the 3 coloured ice catchers through the bottom of the rotating bong.

and from the side

The 3 rasta coloured ice-catcher notches cooling down.

Last edited by trichomefarmer; 08-22-2008 at 09:28 AM.

Various coloured rods for crown's, signature's, carb holes etc...

Last edited by trichomefarmer; 12-13-2008 at 07:53 PM.

In order to show me how the signature process went we ended up using this bong as a demo.

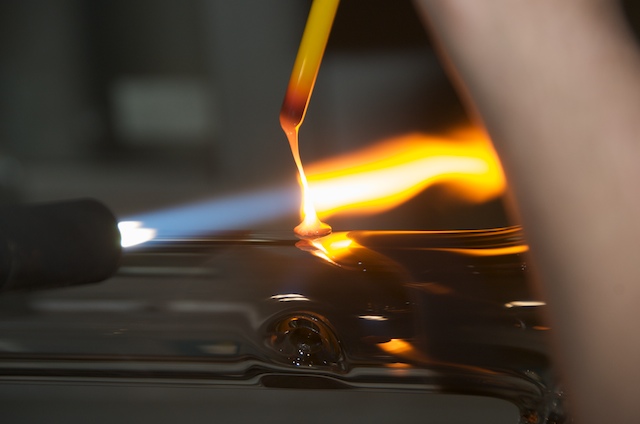

The signature being drawn on.

Melting the signature in the glass wall of the bong

The signature must be smooth with no edges that cause cracks as the bong cools down. Once again reheating the surface area evenly as the bong is manually turned

With the signature and the ice-catcher holes finished it is now time for the bong to cool down before it gets labeled.

Last edited by trichomefarmer; 08-22-2008 at 09:31 AM.

A closer look at the colours.

Sweet pictures man,

an inspiration for me to get a new bong!

makes me kinda wanna try and make my own, looks fun.

FullMeltGuitaristA Guitar Shreddin Full MelterWho can rock out on top.

yer good pics,

Before you ever make fun of an old person, consider that the alternative to old is, not old...

and the only way to achieve not old, is not good

thanks for sharing!

While we are waiting for the bong to cool down let's have a look around.

bongs that need to be finished or repaired.

One of the several work stations.

Kilns, lathes and one guy who has most likely helped make your roor.

A big ass kiln. the kilns are used to heat the bongs up to the same temperature throughout the bong (anealling) i believeThis process strengthens the glass.

Last edited by trichomefarmer; 08-22-2008 at 08:04 PM.

flame polishing a few pics. sorry I didnt really catch the whole process.

Last edited by trichomefarmer; 12-13-2008 at 07:57 PM.